Blood

DIY Mosquito Feeder: How to Feed Blood-Sucking Insects on a Budget

Mosquito control agencies and research centers often maintain lab colonies of mosquitoes for study—and, of course, they need to be fed. As an alternative to pricy commercial feeders, one metropolitan mosquito control agency has developed a simplified feeder that any lab could build for about $30. Here, mosquitoes feed at the Salt Lake City Mosquito Abatement District artificial membrane feeder (“SLAM feeder,” for short). A parafilm cover acts as a membrane and is secured with a rubber band. (Photo courtesy of Christopher Bibbs, Ph.D.)

” data-image-caption=”

Mosquito control agencies and research centers often maintain lab colonies of mosquitoes for study—and, of course, they need to be fed. As an alternative to pricy commercial feeders, one metropolitan mosquito control agency has developed a simplified feeder that any lab could build for about $30. Here, mosquitoes feed at the Salt Lake City Mosquito Abatement District artificial membrane feeder (“SLAM feeder,” for short). A parafilm cover acts as a membrane and is secured with a rubber band. (Photo courtesy of Christopher Bibbs, Ph.D.)

” data-medium-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?fit=390%2C242&ssl=1″ data-large-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?fit=878%2C545&ssl=1″ decoding=”async” fetchpriority=”high” class=”wp-image-20759 size-large” src=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=878%2C545&ssl=1″ alt=”Close-up photograph of a mosquito feeder housing and well. The feeder system consists of a metal well containing a blood source, with a thin film over the blood attached with a rubber band. The well sits in a plastic housing, connected to a electrical cable that powers a small heater inside the housing to warm the blood. Several mosquitoes are visible feeding, and their feeding apparatus can be seen probing into the well.” width=”878″ height=”545″ srcset=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=1024%2C636&ssl=1 1024w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=390%2C242&ssl=1 390w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=768%2C477&ssl=1 768w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=1536%2C954&ssl=1 1536w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=2048%2C1272&ssl=1 2048w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=1200%2C746&ssl=1 1200w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?resize=129%2C80&ssl=1 129w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?w=1756&ssl=1 1756w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder.jpg?w=2634&ssl=1 2634w” sizes=”(max-width: 878px) 100vw, 878px” data-recalc-dims=”1″>

Mosquito control agencies and research centers often maintain lab colonies of mosquitoes for study—and, of course, they need to be fed. As an alternative to pricy commercial feeders, one metropolitan mosquito control agency has developed a simplified feeder that any lab could build for about $30. Here, mosquitoes feed at the Salt Lake City Mosquito Abatement District artificial membrane feeder (“SLAM feeder,” for short). A parafilm cover acts as a membrane and is secured with a rubber band. (Photo courtesy of Christopher Bibbs, Ph.D.)

By Grant Bolton, Ph.D.

Grant Bolton, Ph.D.

” data-image-caption=”

Grant Bolton, Ph.D.

” data-medium-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/grant-bolton.jpeg?fit=390%2C546&ssl=1″ data-large-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/grant-bolton.jpeg?fit=446%2C624&ssl=1″ decoding=”async” class=”wp-image-20753″ src=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/grant-bolton.jpeg?resize=125%2C175&ssl=1″ alt=”Grant Bolton, Ph.D. ” width=”125″ height=”175″ srcset=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/grant-bolton.jpeg?w=446&ssl=1 446w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/grant-bolton.jpeg?resize=390%2C546&ssl=1 390w, https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/grant-bolton.jpeg?resize=57%2C80&ssl=1 57w” sizes=”(max-width: 125px) 100vw, 125px” data-recalc-dims=”1″>

Grant Bolton, Ph.D.

What does it take to maintain eight or more species of mosquitoes in an insectary?

A whole lot of blood!

However, finding a sustainable and economical way to feed female mosquitoes a blood meal so they can reproduce can be a significant challenge. Without options that are both affordable and scalable, large-scale research is often limited to institutions with large budgets.

That was the challenge that researchers at the Salt Lake City Mosquito Abatement District (SLCMAD) set out to address when they built a low-cost feeding device to keep multiple species of mosquitoes alive and reproducing. They share the design for the device and their results showing its viability in an article published in August in the open-access Journal of Insect Science.

Developing a DIY Solution

Led by Laboratory Director Christopher Bibbs, Ph.D., the SLCMAD’s independent vector monitoring station in Utah surveys mosquitoes for pesticide resistance, and it requires keeping several known strains of non-resistant and resistant mosquito populations in their laboratory. That adds up to a lot of blood feeding for these mosquitoes.

While there are several do-it-yourself (DIY) designs out there, many of them use disposable materials that produce a lot of waste and aren’t as reliable as commercially available options. These commercial midrange devices are often easier to use, more efficient, and produce less waste. However, the downside is that they are more expensive.

“Scaling an insectary at $800 to $2,000 per device isn’t in the budget for many smaller universities and institutions,” says Bibbs. “They may only have one or two researchers working on blood-feeding insects, but they still need to maintain and scale their insectaries in a sustainable way.”

Another problem with relying on commercial models is that the supply chain could break down at any minute and researchers would then be unable to access the parts or products they need to keep their colonies surviving and their research progressing. “For us at the Salt Lake City Mosquito Abatement District, it was cheaper to make it,” Bibbs says.

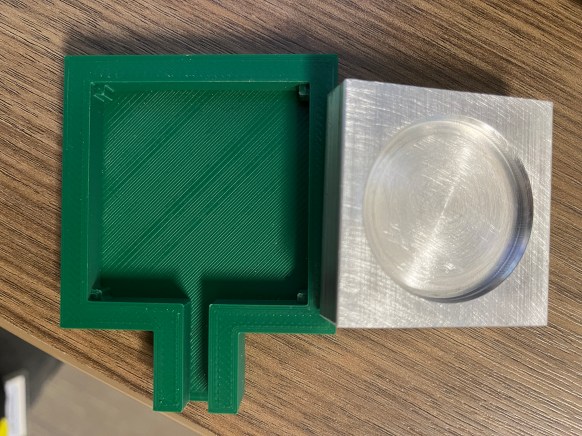

The housing (left) is 3D printed and holds the aluminum well in place. A flat film adhesive heater is placed under the block to heat the blood. (Photo courtesy of Christopher Bibbs, Ph.D.)

” data-medium-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well.jpg?fit=390%2C293&ssl=1″ data-large-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well.jpg?fit=878%2C659&ssl=1″ src=”https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well.jpg” srcset=”https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-1-scaled.jpg 3000w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-2.jpg 390w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-3.jpg 1024w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-4.jpg 768w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-5.jpg 1536w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-6.jpg 2048w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-7.jpg 1200w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-8.jpg 800w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-9.jpg 600w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-10.jpg 400w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-11.jpg 200w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-12.jpg 107w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-13.jpg 1756w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-housing-and-well-14-scaled.jpg 2634w” width=”582″ height=”436″ loading=”lazy” data-original-width=”582″ data-original-height=”436″ itemprop=”http://schema.org/image” title=”SLAM mosquito feeder housing and well” alt=”Overhead view of a green plastic square tray with a channel for an electrical cord on the bottom side. Next to the tray is a square piece of aluminum with a circular well carved into it. The aluminum tray is the correct size to fit into the housing.”>

The housing (left) is 3D printed and holds the aluminum well in place. A flat film adhesive heater is placed under the block to heat the blood. (Photo courtesy of Christopher Bibbs, Ph.D.)

Readily available electrical parts can be assembled to accurately heat the blood to the proper temperatures for mosquito feeding. That temperature can be maintained for up to 2 hours. (Photo courtesy of Christopher Bibbs, Ph.D.)

” data-medium-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts.jpg?fit=390%2C293&ssl=1″ data-large-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts.jpg?fit=878%2C659&ssl=1″ src=”https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts.jpg” srcset=”https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-1-scaled.jpg 3000w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-2.jpg 390w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-3.jpg 1024w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-4.jpg 768w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-5.jpg 1536w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-6.jpg 2048w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-7.jpg 1200w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-8.jpg 800w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-9.jpg 600w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-10.jpg 400w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-11.jpg 200w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-12.jpg 107w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-13.jpg 1756w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-electrical-parts-14-scaled.jpg 2634w” width=”288″ height=”216″ loading=”lazy” data-original-width=”288″ data-original-height=”216″ itemprop=”http://schema.org/image” title=”SLAM mosquito feeder electrical parts” alt=”Photo of electrical components in a mosquito feeder system. The image shows a collection of two parts. One hash a plug to go into a standard electrical outlet, with a long black coiled cord. The other component shows a square aluminum well sitting in a plastic housing connected to a black electrical cord.”>

Readily available electrical parts can be assembled to accurately heat the blood to the proper temperatures for mosquito feeding. That temperature can be maintained for up to 2 hours. (Photo courtesy of Christopher Bibbs, Ph.D.)

Screws can be added to the device to position it at an angle to make it easier for certain species of mosquito to feed. (Photo courtesy of Christopher Bibbs, Ph.D.)

” data-medium-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted.jpg?fit=390%2C293&ssl=1″ data-large-file=”https://i0.wp.com/entomologytoday.org/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted.jpg?fit=878%2C659&ssl=1″ src=”https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted.jpg” srcset=”https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-1-scaled.jpg 3000w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-2.jpg 390w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-3.jpg 1024w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-4.jpg 768w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-5.jpg 1536w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-6.jpg 2048w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-7.jpg 1200w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-8.jpg 800w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-9.jpg 600w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-10.jpg 400w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-11.jpg 200w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-12.jpg 107w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-13.jpg 1756w, https://medicalguru.us/wp-content/uploads/2023/09/slam-mosquito-feeder-tilted-14-scaled.jpg 2634w” width=”288″ height=”216″ loading=”lazy” data-original-width=”288″ data-original-height=”216″ itemprop=”http://schema.org/image” title=”SLAM mosquito feeder tilted” alt=”Close-up photo of the well and housing sitting on a table. Two metal screws extend from below housing near the side where the cord is attached, such that the housing is tilted at roughly a 30 degree angle.”>

Screws can be added to the device to position it at an angle to make it easier for certain species of mosquito to feed. (Photo courtesy of Christopher Bibbs, Ph.D.)

How It’s Made

The device consists of a milled aluminum well, inserted into a 3D-printed housing. The blood is then inserted into the well and heated by a flat film adhesive heater that can quickly heat and maintain the blood at the proper temperature for the mosquitoes. A parafilm membrane is stretched over the well of blood and securely fastened. Bibbs’ and colleagues’ study found that their device worked as efficiently as available Hemotek models but for a fraction of the price.

Cost to build one yourself? Around $30.

One of the benefits of a DIY midrange device is that the initial price to start an insectary can be drastically reduced, and the device has several uses as well. The study also found that, by angling the device at a 45-degree angle, certain species of mosquito actually feed more efficiently. And for those aggressive feeding species? There’s a double well design that can offer extra surface area and blood without the extra work.

The device—which Bibbs’ team dubs the “SLAM feeder” (the acronym being short for Salt Lake City Mosquito Abatement District artificial membrane)—can also be adapted to other blood-feeding insects, other membranes can be used to allow for experimentation, and the devices can be used for feeding or repellency trials.

Making Mosquito Feeding More Accessible

Bibbs and the team at the Salt Lake City Mosquito Abatement District have made the 3D-printed plans available for free on ThingiVerse and, with a little bit of technical skills and the instructions found in their published article, anyone can have a colony of blood-feeding insects up and running with minimum startup costs.

As Bibbs and colleagues suggest, the SLAM feeder could also be a great help to research centers in developing countries that lack big budgets or the availability of market solutions, without sacrificing quality. A DIY option that is both efficient and sustainable can open up many research opportunities for the future.

Grant Bolton, Ph.D., is a freelance writer and voice actor with a Ph.D. in entomology based in western Missouri. Email: [email protected].