Infection

Novel Surgical Implant Kills Infection-Causing Bacteria Without Compromising Tissue Integration

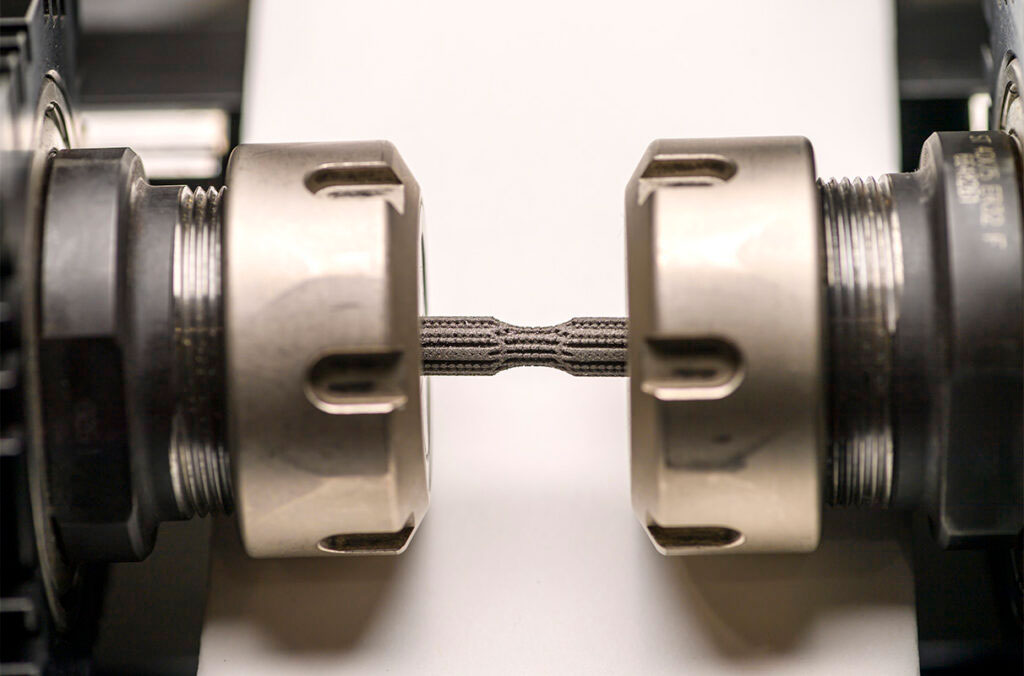

Image: Researchers tested the new 3D-printed material’s resistance to fatigue (Photo courtesy of WSU Photo Services)

Around the world, numerous surgeries, including hip and knee replacements, are routinely performed. One major complication of these procedures is bacterial colonization on the implants, a primary factor leading to implant failure and adverse postoperative outcomes. Typically, the materials used in these implants, developed over half a century ago, lack inherent resistance to infections. While antibiotics are commonly used as a preventive measure, dangerous infections can still arise post-surgery or as delayed secondary infections. In cases where infections form a thin biofilm on the implant, systemic antibiotics are employed. However, approximately 7% of these surgeries require revision, involving implant removal, thorough cleaning, antibiotic treatment, and re-implantation.

Researchers at Washington State University (Pullman, WA, USA) have designed a new surgical implant that has demonstrated a remarkable 87% efficacy in eliminating staph infection-causing bacteria in lab tests. This breakthrough could significantly enhance infection control in various common surgical procedures. The research team utilized 3D printing technology to enhance a typical titanium alloy implant by integrating 10% tantalum, known for its corrosion resistance, and 3% copper. The copper component effectively ruptures the cell walls of most bacteria upon contact.

Moreover, the addition of tantalum promotes healthy cell integration and bone tissue growth, thus aiding in the patient’s recovery. The WSU researchers dedicated three years to a comprehensive examination of their implant prototype, analyzing its mechanical strength, biological compatibility, antibacterial effectiveness, and wear properties. This evaluation extended to both lab settings and animal model studies. A crucial aspect of their research was ensuring that metal ions from the implant do not erode into adjacent tissues, which could lead to toxicity. Moving forward, the team aims to improve the bacterial elimination rate to surpass the 99% standard without affecting tissue integration. Additionally, they are focusing on ensuring the implant’s durability under real-life conditions, such as the demands of activities like hiking for knee replacement patients.

“Infection is a problem for which we do not have a solution,” said Amit Bandyopadhyay, Boeing Distinguished Professor in WSU’s School of Mechanical and Materials Engineering. “In most cases, the implant has no defensive power from the infection. We need to find something where the device material itself offers some inherent resistance — more than just providing drug-based infection control. Here we’re saying, why not change the material itself and have inherent antibacterial response from the material itself?”

Related Links:

Washington State University